|

Note: Alphatec® is not supported by a Dulux warranty and where colour retention is paramount, we recommend the Duratec® Intensity or Eternity powder coat ranges. It is ideal for use:

Developed for use over various substrates including steel and aluminium on interior and non-habitable (architectural) exterior product applications combined with excellent overall performance.

Examples include: interior furniture and storage equipment, electrical cabinets other industrial metal products such as bicycles, garden tools, lawn mowers, and automotive components.

Consult Dulux for the most appropriate Industrial powder coating product for your end use.

Ideal for application over:

Alphatec®

Superior: 5

Excellent: 4

Very good: 3

Good: 2

OK: 1

Not Applicable: 0

Description of measures:

Visit the contact us page to get in touch.

The pre-treatment process should be capable of meeting the performance outputs as described in AS3715. Compliance to appropriate process parameters is essential in ensuring compliance to etch, conversion coating weights (time/concentration) and conductivity of the final rinse.

The etch process is a very important stage of pre-treatment and close consultation with your pre-treatment supplier is strongly recommended to ensure optimum adhesion & corrosion resistance is obtained. As an approximate guide:

This is the next pre-treatment process for aluminium to ensure that it is suitably prepared for coating. It is recommended that Chrome conversion weights be a minimum of 431mg/m2, but advice from pre-treatment suppliers should be taken into consideration.

Final rinse is to ensure optimum surface preparation prior to coating.

Care should be taken with handling to ensure health and safety measures are met and that the substrate is not contaminated. Pre-treated aluminium must be handled very carefully with clean lint-free gloves and powder coated within the time specified by the pre-treatment supplier - this is generally within 16 to 48 hours.

If your site uses a dry off oven to assist in the pre-treatment process please ensure:

PREPARATION FOR STEEL SUBSTRATES:

Electrostatic Spray

| Metal Temperature (°C) | Time (minutes) | Comments |

| 210° | 8 mins minimum | Metal temperature (Matt products). |

| 200° | 10 mins minimum | Metal temperature (Matt products). |

| 190° | 15 mins minimum | Metal temperature (Matt products). |

| 210° | 4 mins minimum | Metal temperature (Gloss & Satin products). |

| 200° | 5 mins minimum | Metal temperature (Gloss & Satin products). |

| 180° | 8 mins minimum | Metal temperature (Gloss & Satin products). |

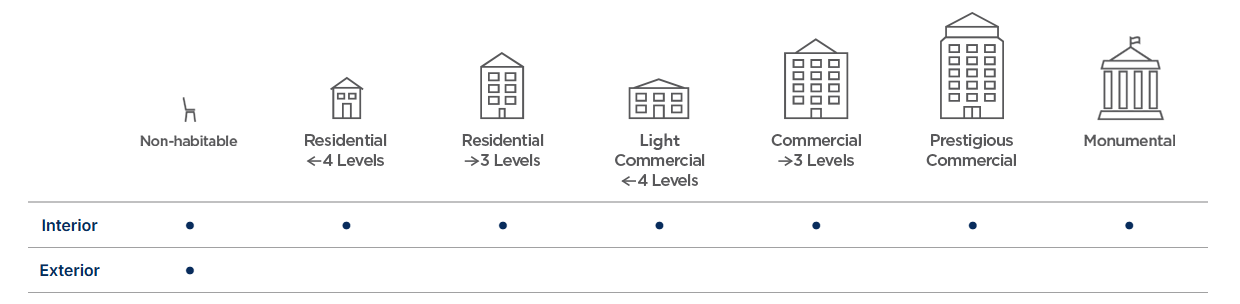

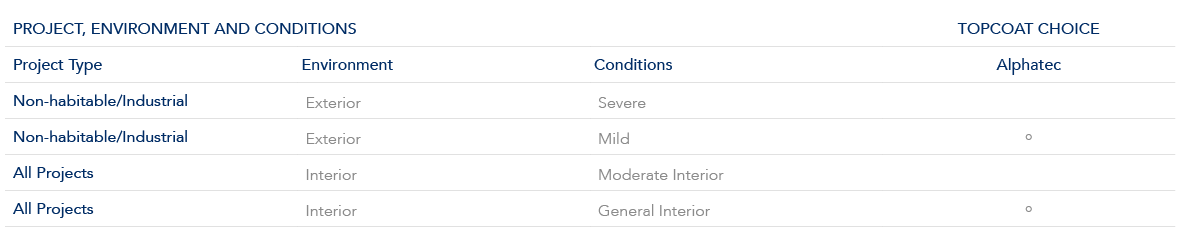

Use the following table to help identify where Alphatec® can be applied on aluminium projects. Refer to the conditions information to determine the environment that your project will be exposed to.

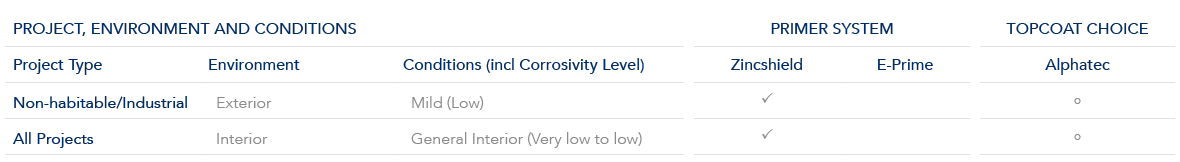

Use the following table to help identify where Alphatec® can be applied on steel projects. Refer to the conditions information to determine the environment that your project will be exposed to.

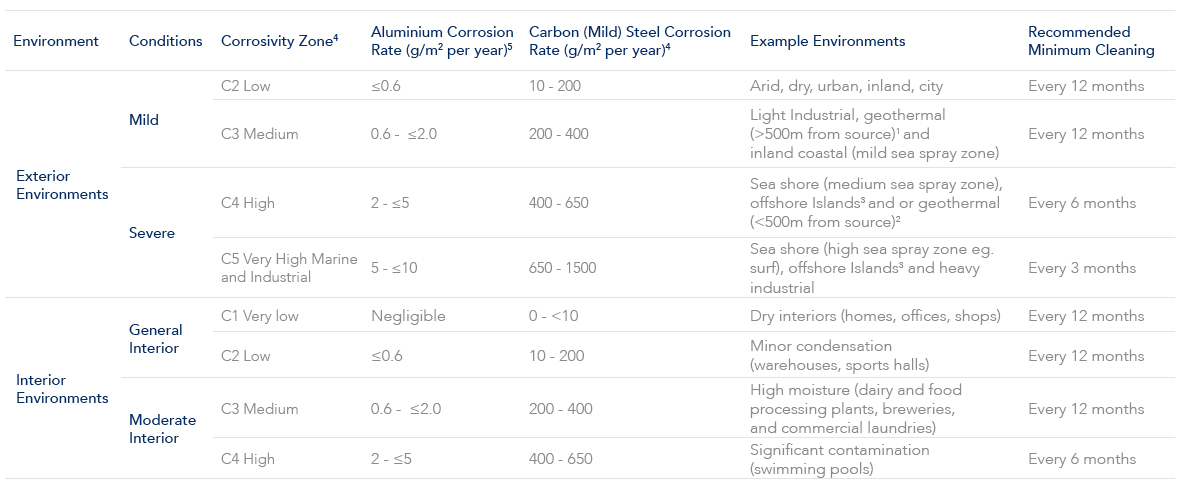

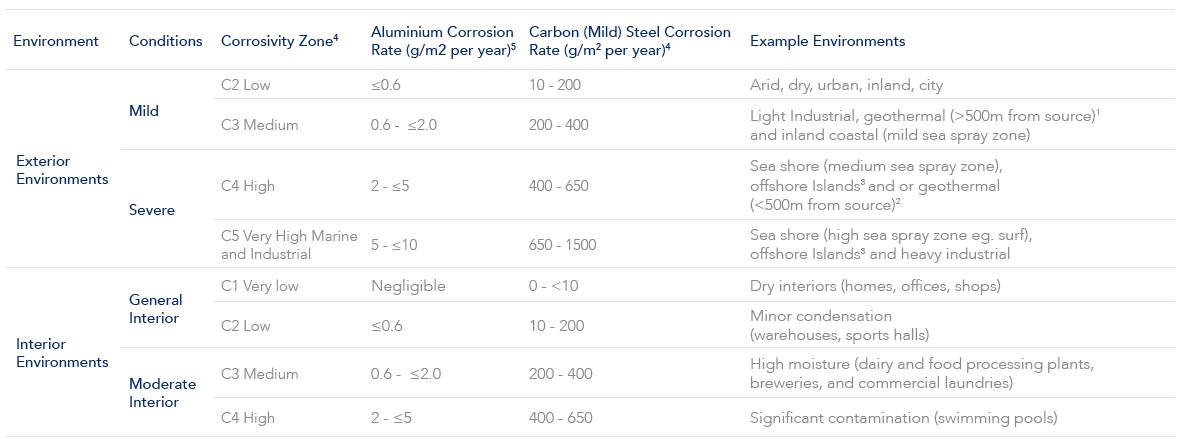

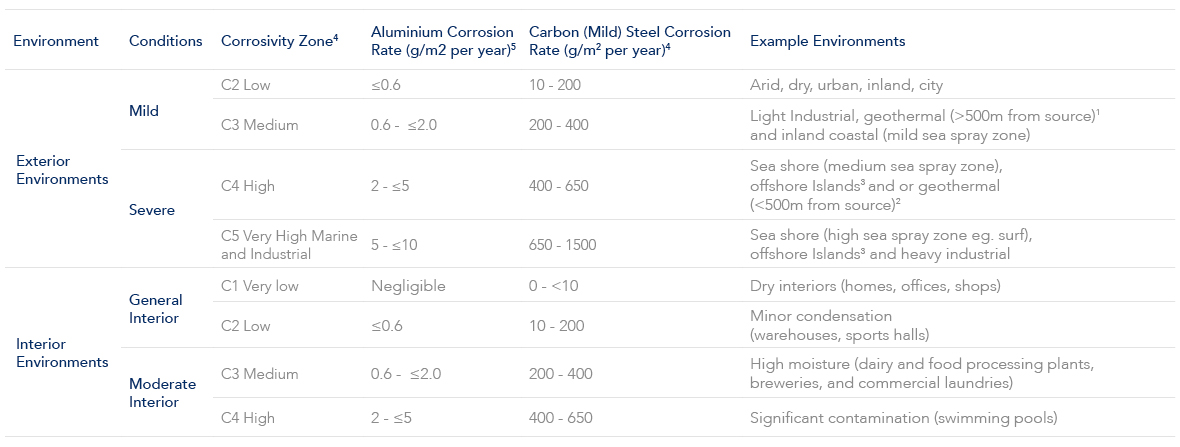

Use the following table which references AS2312.1, SNZTS 3404 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories.

Advice Line

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project.

Call 0800 800 975

Colours displayed should be used as a guide for your colour selection.

Always confirm your colour choice with a production line prepared swatch for final colour approval.

* Only Dulux Accredited Powder Coaters are able to issue our Dulux Alumi Shield™ and Steel Shield™ warranties after demonstrating their capability to meet stringent quality conditions and international standards.

Bright solid colours and pearlescent finishes that produce a big impact, delivered with tough polyester thermosetting powder. Recommended usage includes commercial fitouts, furniture, electrical switchboards and aftermarket automotive components.

Gloss

28859623

Gloss

2884480G

Gloss

28858613

Gloss

2886536G

Gloss

28833617

Gloss

28850735

Gloss

28857262

Satin

2886538S

Gloss

28896905

Gloss

28858413

Gloss

28857273

Satin

28858566

Gloss

28851439

Gloss

2884155G

Gloss

28819990

Gloss

28858571

Gloss

2884008G

Gloss

28857074

Satin

9617380S

Satin

9617182S

Gloss

9617960G