|

|||||

|

|

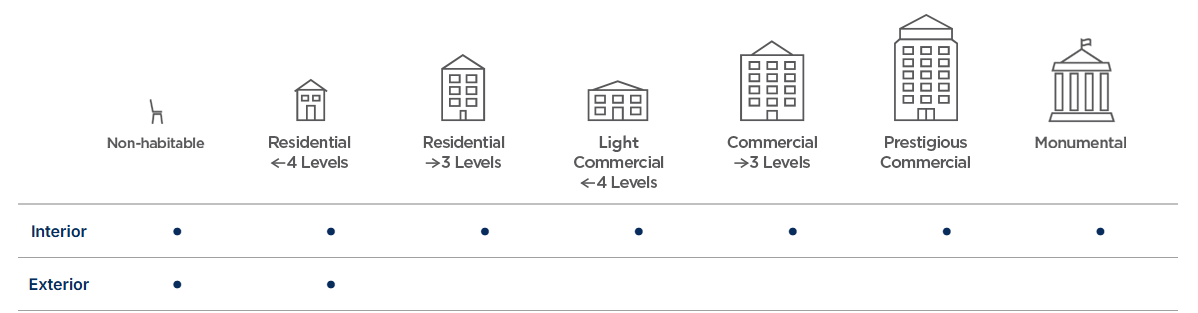

It is ideal for use:

Duralloy is only suitable for coastal environments >100m from the high tide line and are NOT suitable in strongly acidic or caustic environments so the the pH must be between 5 and 9.

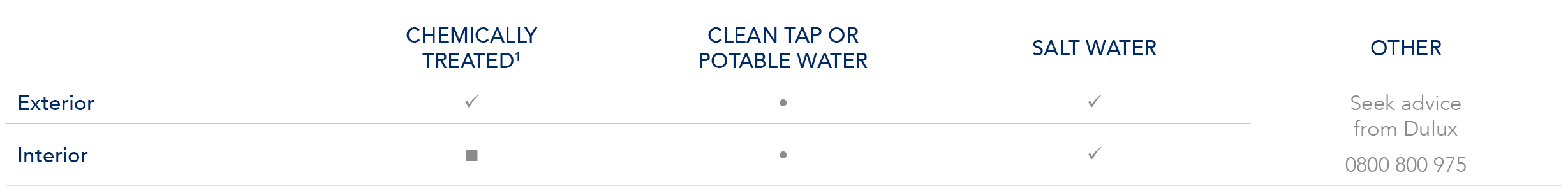

Please refer to the 'Interior and exterior environments close to liquids other than the sea' section for warranty implications for in such environments.

*Warranties are only valid when applied by a Dulux Accredited or Dulux Prime Accredited Powder Coater to the warranty specification on recommended projects, and subject to specified warranty terms and conditions.

Duralloy®

Superior: 5

Excellent: 4

Very good: 3

Good: 2

OK: 1

Not Applicable: 0

Steel substrates shall be prepared as follows:

1. Wash and degrease all surfaces to be coated in accordance with AS1627.1 with a free-rinsing, neutral/alkaline detergent, in strict accordance with the manufacturer’s written instructions and all safety warnings.

2. Wash with fresh potable water and ensure that all soluble salts are removed. Testing if required can be done in accordance with AS 3894.6 for the determination of residual contaminants.

3. Grind all sharp edges with a power tool to a minimum radius of 2mm.

4. Hand or power tool clean welds to AS1627.2 to remove roughness. Remove filings, preferably by vacuum.

5. Abrasive blast clean all steel surfaces to be powder coated in accordance with AS 1627.4 to the visual cleanliness standard of SA 2.5. Use a medium that will generate a surface profile of 35 to 65 microns. In situations where it is not possible to prepare your item on all surfaces as described above, for long term protection against corrosion it is strongly recommended whenever possible, that an alternative substrate such as aluminium be considered. Failure to suitably prepare your steel substrate may void your Steel Shield™ warranty.

6. The steel must be coated within 4 hours of blasting and stored in an area which is clean and dry. Dulux Accredited Powder Coaters must comply with the metal pre-treatment guidelines set out in the Accredited Steel Shield™ Manual.

Electrostatic Spray

Metal Temperature:

210° : 4 mins minimum

200° : 5 mins minimum

180° : 8 mins minimum

Please note: All RapidCure products can be applied at standard temperatures, but benefits from possible reduction in energy consumption or faster line speeds will be lost.

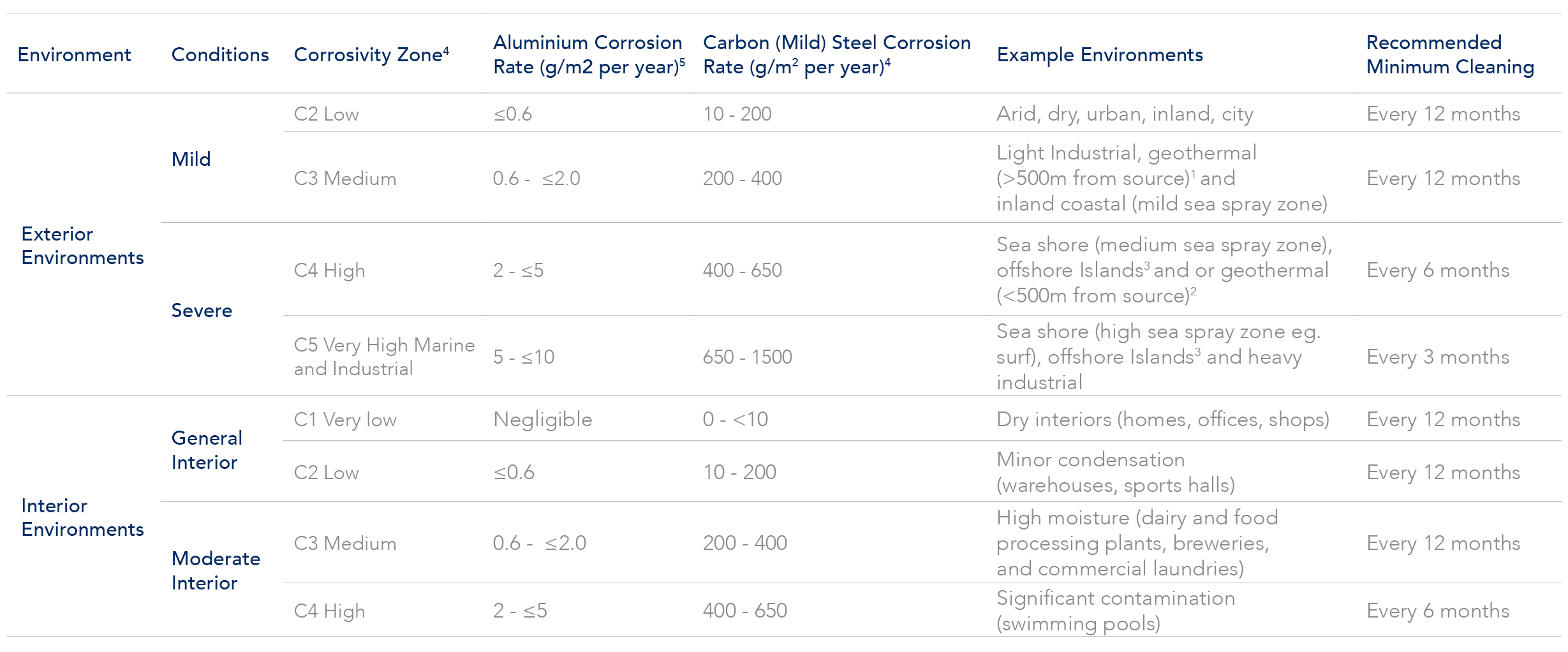

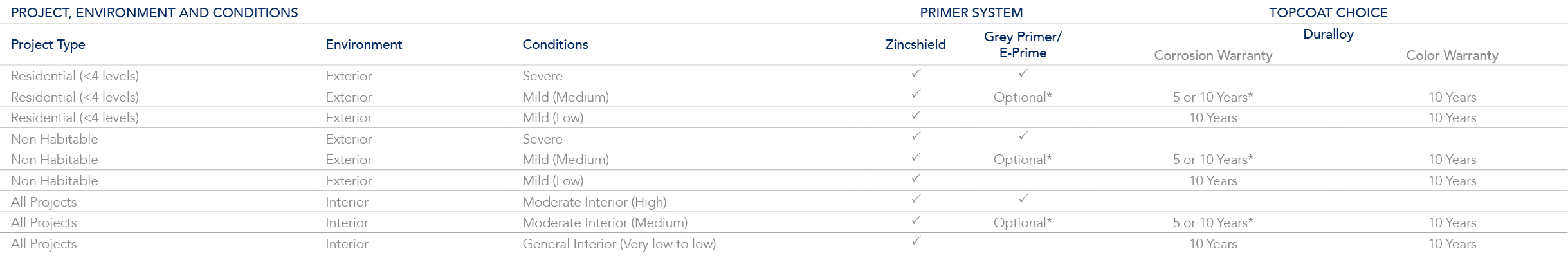

Use the tables below to determine the appropriate the product choice you have to gain a Alumi Shield™ warranty by determining the environment that your project will be exposed to. Use this together with the Dulux Macroclimate Corrosivity Corrosivity Zone Maps of New Zealand Guide, available here, the online Dulux SpecMap tool, available here.

Use the tables below to determine the appropriate the product choice you have to gain a Steel Shield™ warranty by determining the environment that your project will be exposed to. Use this together with the Dulux Macroclimate Corrosivity Corrosivity Zone Maps of New Zealand Guide, available here, the online Dulux SpecMap tool, available here. Click on the table below for a larger version.

All Dulux powder products are NOT suitable in strongly acidic or caustic environments so the PH must be between 5 and 9.

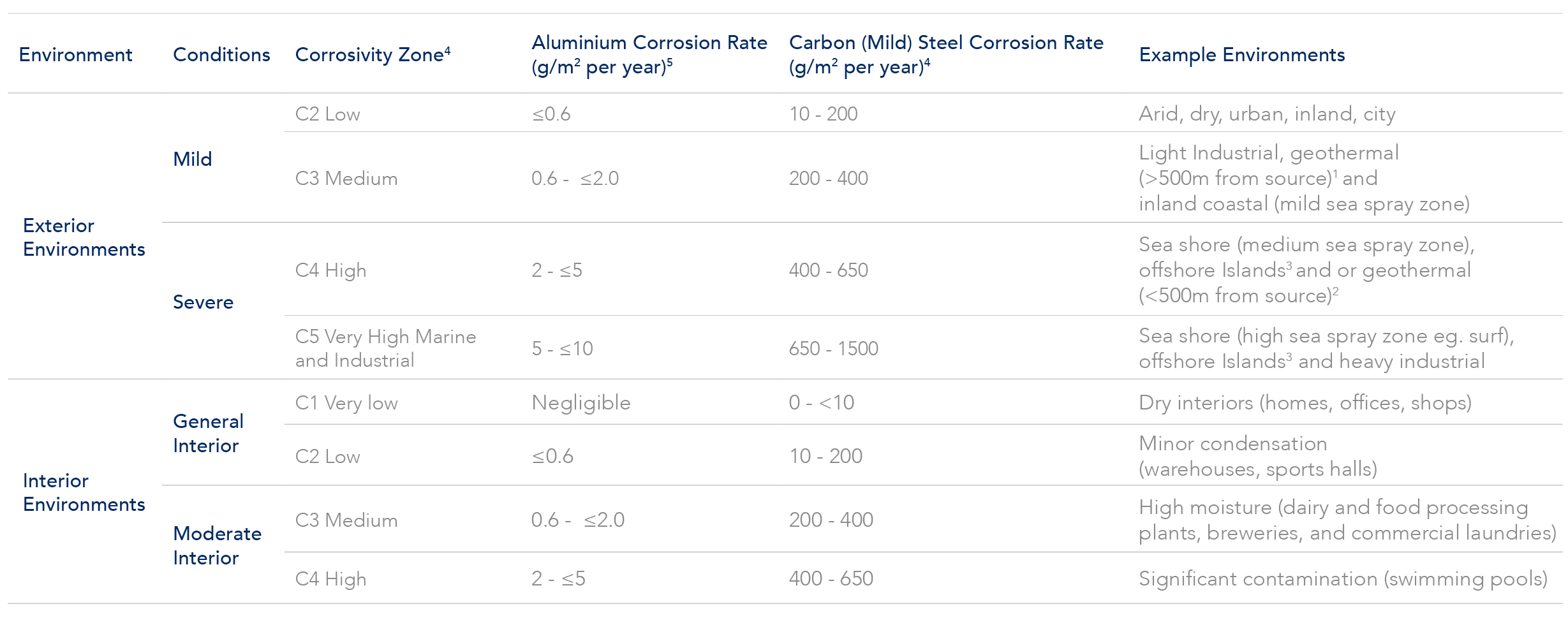

All Dulux powder products are NOT suitable in strongly acidic or caustic environments so the PH must be between 5 and 9.Use the following table which references AS 2312.1, SNZ TS 3404 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories. To pinpoint your projects corrosivity zone this table should be used together with the Dulux Macroclimate Corrosivity Zone Maps of New Zealand Guide, available here, or Dulux SpecMap tool available here.

1. Geothermal environments greater than 500m of a bore, mud pool, steam vent, or other source with a pH between 5 and 9. For pH outside this consult Dulux.

2. Geothermal hot spots within 500m of a bore, mud pool, steam vent, or other source.

3. All offshore islands including Waiheke Island, Stewart Island, Fraser Island and Pacific islands eg PNG, Fiji, Samoa, Tonga, Tahiti, Noumea

4. The corrosion rates for the first year of exposure for the different corrosivity categories of Aluminium and Carbon (Mild) Steel are determined by the following standards:

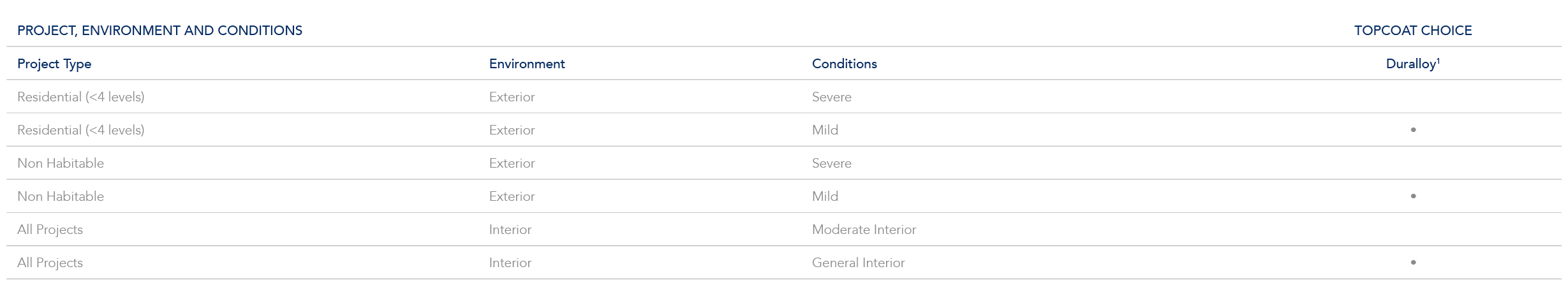

On pre-treated architectural aluminium when applied by a Dulux Accredited Powder Coater to the warranty specification on recommended project types and conditions.

For more information on our Dulux Alumi Shield™ warranty program click here.

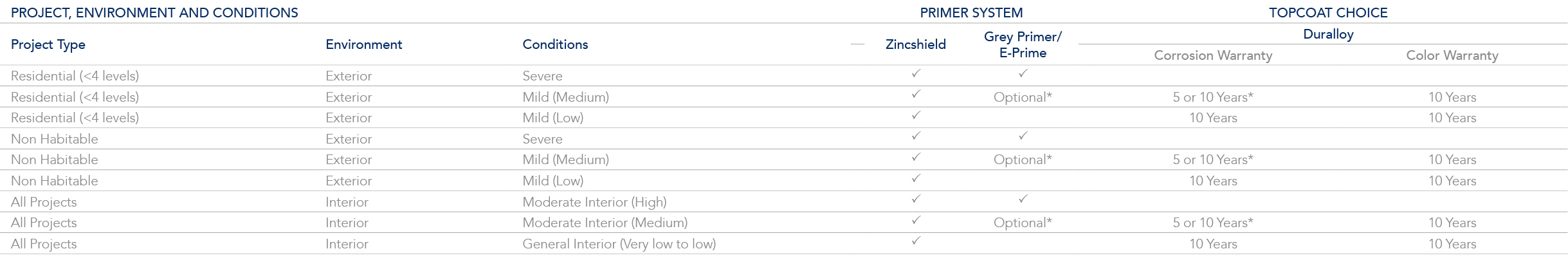

On mild steel, bright/semi bright steel, black steel and blue steel as part of the Steel Shield warranty system when applied by a Dulux Accredited Powder Coater to the warranty specification on recommended project types and conditions.

For more information on our Dulux Steel Shield™ warranty program click here.

Environments must be:

Please note chemically treated water includes antimicrobial treatments, e.g. in pools, anti-corrosive chemicals, and soapy water in bathrooms and showers.

Only Dulux Accredited Powder Coaters are able to issue our Dulux Alumi Shield™ and Steel Shield™ warranties after demonstrating their capability to meet stringent quality conditions and international standards.

For more information click here.

The Duralloy solid colour range is a collection of popular solid colours including COLORSTEEL® colours^, delivered with warranty grade advanced durable polyester thermosetting powder.

Gloss

9151405G

Matt

9151267M

Satin

91558851

Gloss

9151406G

Satin

91585355

Gloss

9151404G

Matt

9151274M

Satin

91558853

Satin

91558854

Gloss

91596007

Matt

9153144M

Satin

91558804

Matt

9153155M

Matt

9153272M

Matt

9154410M

Matt

9153143M

Matt

9153141M

Satin

91558802

Matt

9153142M

Matt

9151266M

Satin

91597123

Matt

9152068M

Satin

91558855

Satin

9157967S

Matt

9157327M

Satin

91558718

Matt

9157400M

Matt

9157304M

Gloss

9157968G

Gloss

9157196G

Satin

91532786

Matt

9157511M

Satin

91597128

Matt

9157401M

Satin

91558714

Matt

9153065M

Matt

9152111M

Satin

91558806

Matt

9156101M

Matt

9158159M

Satin

91556995

Matt

9154194M

Matt

9154114M

Matt

9155498M

Matt

9155247M

Matt

9155197M

Matt

9155248M

Matt

9155234M

Matt

9155147M

Matt

9155063M

Satin

91558601

Matt

9156541M

Matt

91552027

Matt

9156103M

Satin

91558555

Matt

9156102M

Satin

91558559

Satin

91557290

Matt

9156259M

Matt

9156064M

Satin

91558557

Matt

9158033M

Matt

9156193M

Matt

91558751

Matt

91558752

Matt

9157217M

Satin

91558706

Matt

9157551M

Matt

9157589M

Matt

91558701

Matt

9157324M

Satin

91597129

Matt

9157484M

Matt

9159145M

Matt

9157590M

Matt

9157167M

Satin

91558711

Matt

9159058M

Satin

91558707

Matt

9158096M

Satin

91558716

Matt

9157404M

Matt

9159041M

Satin

91558651

Gloss

9159255G