![]()

It is ideal for use:

Steel substrates shall be prepared as follows:

1. Wash and degrease all surfaces to be coated in accordance with AS1627.1 with a free-rinsing, neutral/alkaline detergent, in strict accordance with the manufacturer’s written instructions and all safety warnings.

2. Wash with fresh potable water and ensure that all soluble salts are removed. Testing if required can be done in accordance with AS 3894.6 for the determination of residual contaminants.

3. Grind all sharp edges with a power tool to a minimum radius of 2mm.

4. Hand or power tool clean welds to AS1627.2 to remove roughness. Remove filings, preferably by vacuum.

5. Abrasive blast clean all steel surfaces to be powder coated in accordance with AS 1627.4 to the visual cleanliness standard of SA 2.5. Use a medium that will generate a surface profile of 35 to 65 microns. In situations where it is not possible to prepare your item on all surfaces as described above, for long term protection against corrosion it is strongly recommended whenever possible, that an alternative substrate such as aluminium be considered. Failure to suitably prepare your steel substrate may void your Steel Shield™ warranty.

6. The steel must be coated within 4 hours of blasting and stored in an area which is clean and dry. Dulux Accredited Powder Coaters must comply with the metal pre-treatment guidelines set out in the Accredited Steel Shield™ Manual.

Application Method

Electrostatic Spray

Cure Schedule

Assuming top coat applied within 12 hours, a partial cure may be possible - consult the TDS for further advice.

This partial cure is referred to as a green cure. Green cured metal is prone to chipping/cracking if not handled with care. Ensure green cured metal is protected from mechanical damage caused by unloading/stacking. Use top coat cure schedule to complete cure of Zincshield®.

A topcoat must always be applied.

It is recommended that Zincshield® be top coated within 12 hours due to a possible moisture uptake of the coating

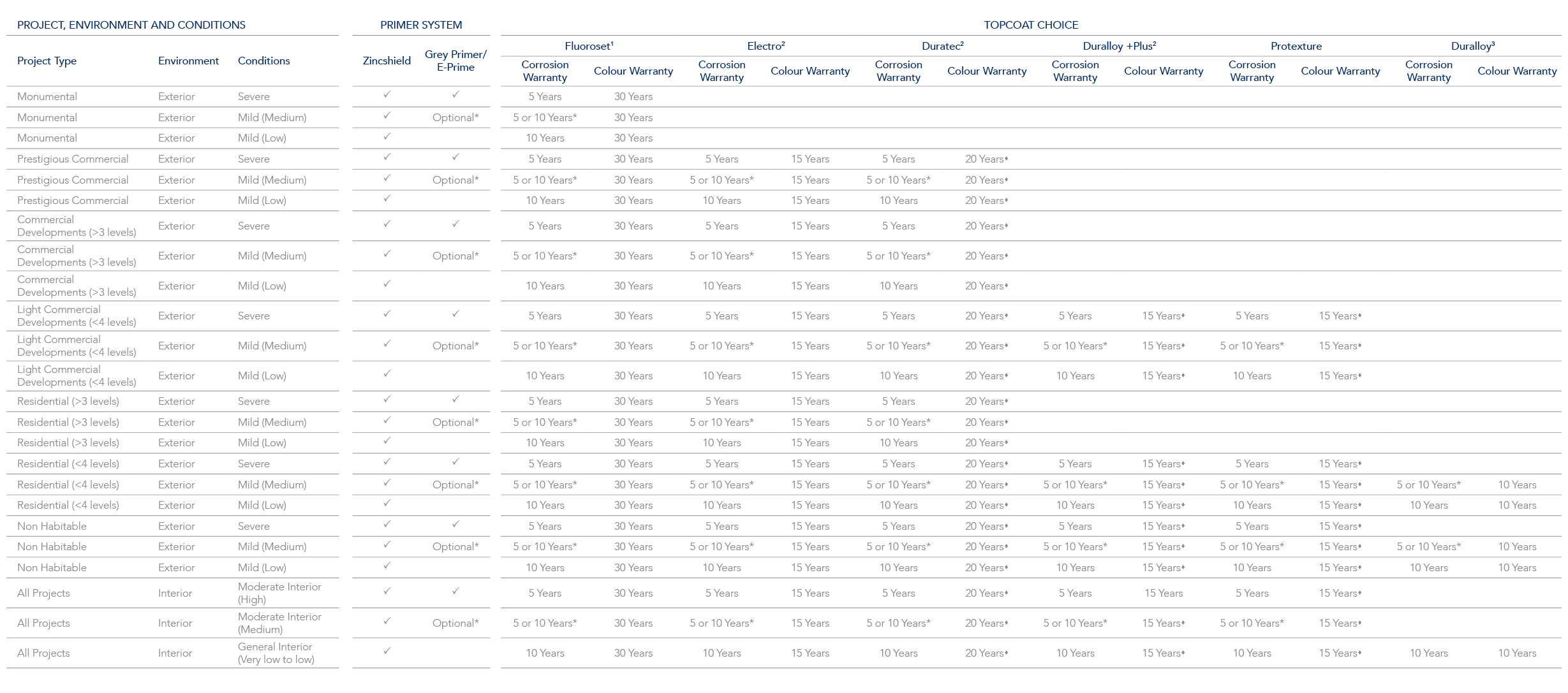

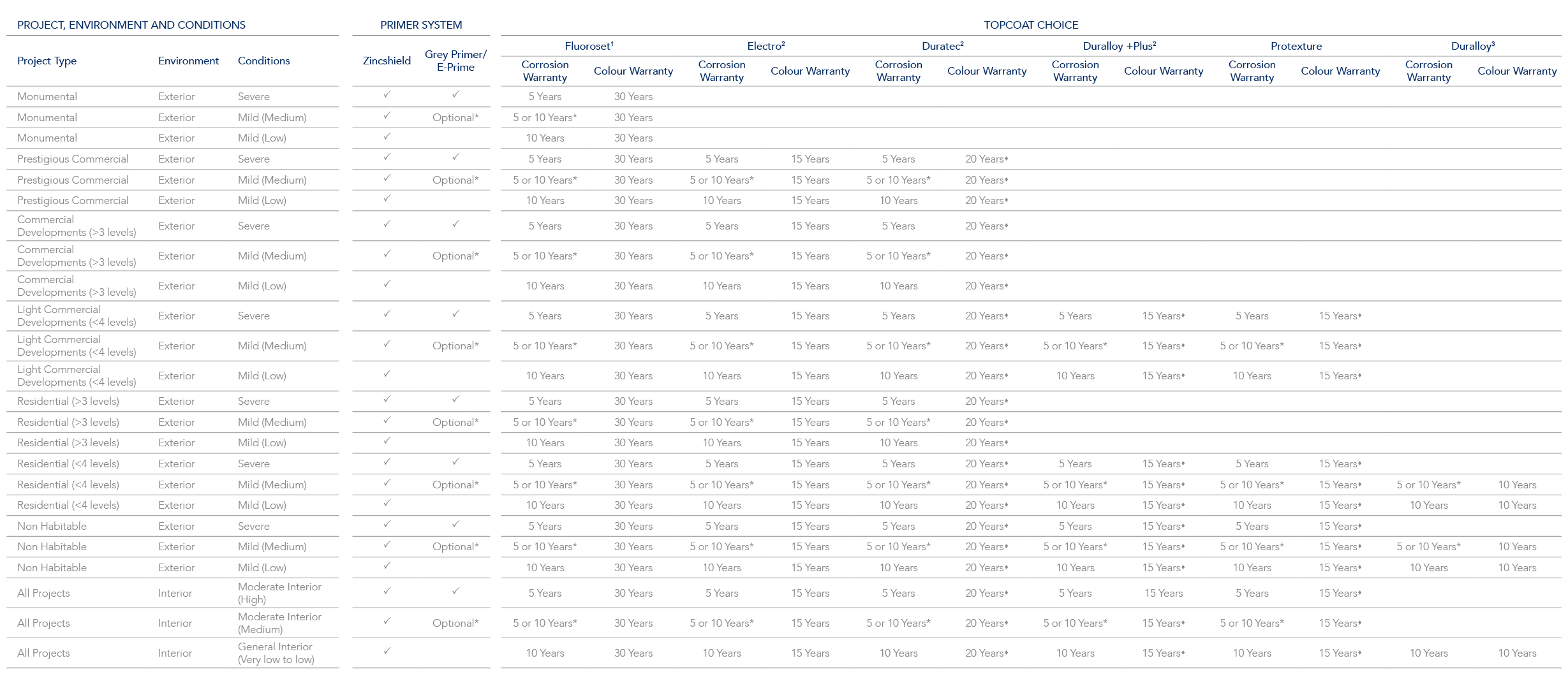

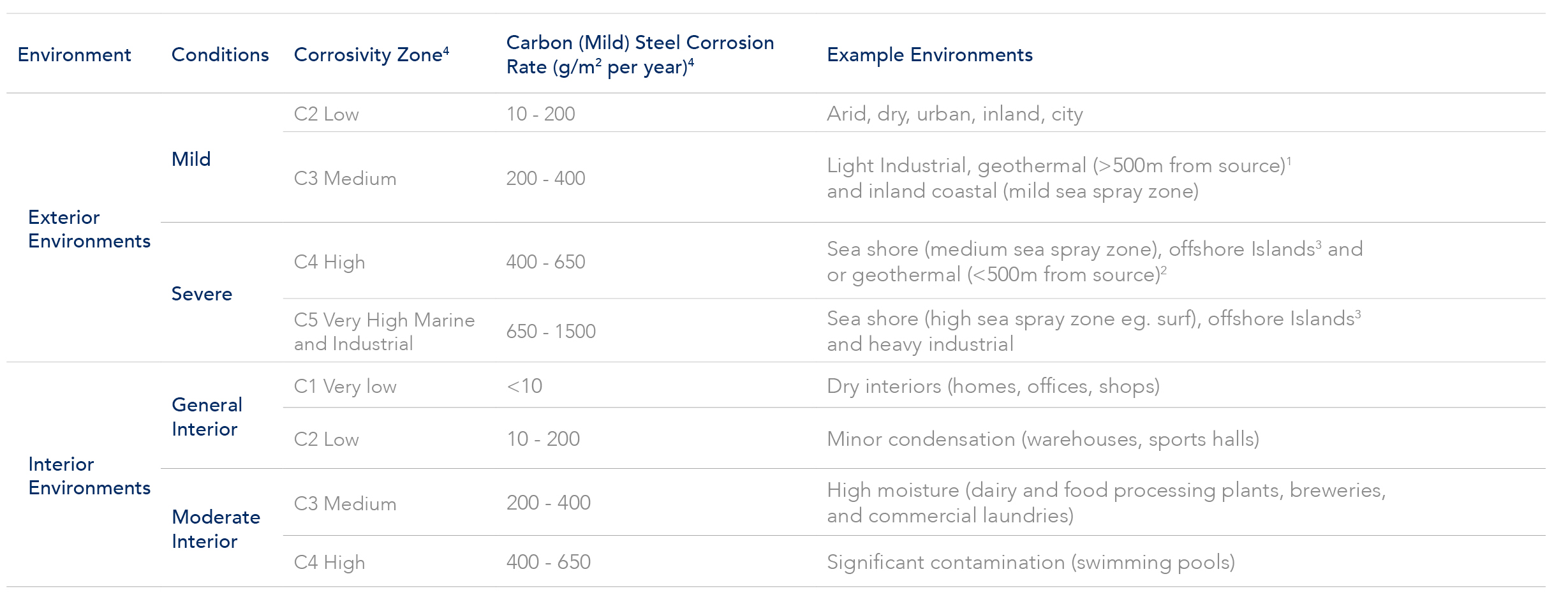

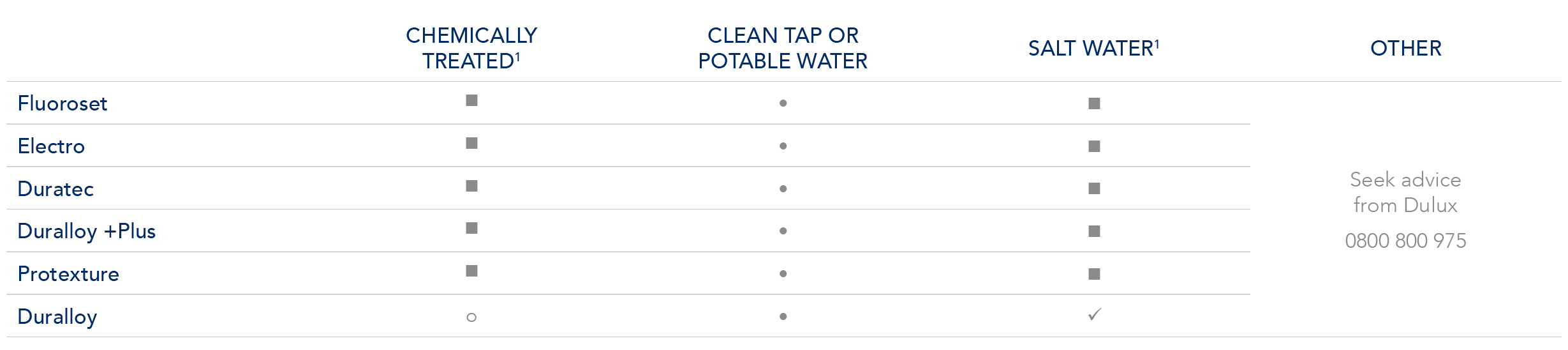

Zincshield is a key component of the Dulux Steel Shield™ warranty systems. Use the following table to help identify the product choice you have to gain a Steel Shield™ warranty on your project and where Zincshield is appropriate. Refer to the conditions information to determine the environment that your project will be exposed to. Click on the table below for a larger version.

Zincshield is a zinc rich epoxy modified thermosetting powder primer designed to inhibit rust and subsequent adhesion loss on ferrous metals and is a key component of Dulux Steel Shield™ Warranty systems suitable for use with top coats from the Fluoroset®, Duratec®, Electro®, and Duralloy® ranges.

Matt

9907036M