|

|

It is ideal for use:

Superior: 5

Excellent: 4

Very good: 3

Good: 2

OK: 1

Not Applicable: 0

Description of measures:

Visit the contact us page to get in touch.

Electrostatic Spray

Metal Temperature:

210° : > 20 mins

200° : >25 mins

195° : >30 mins

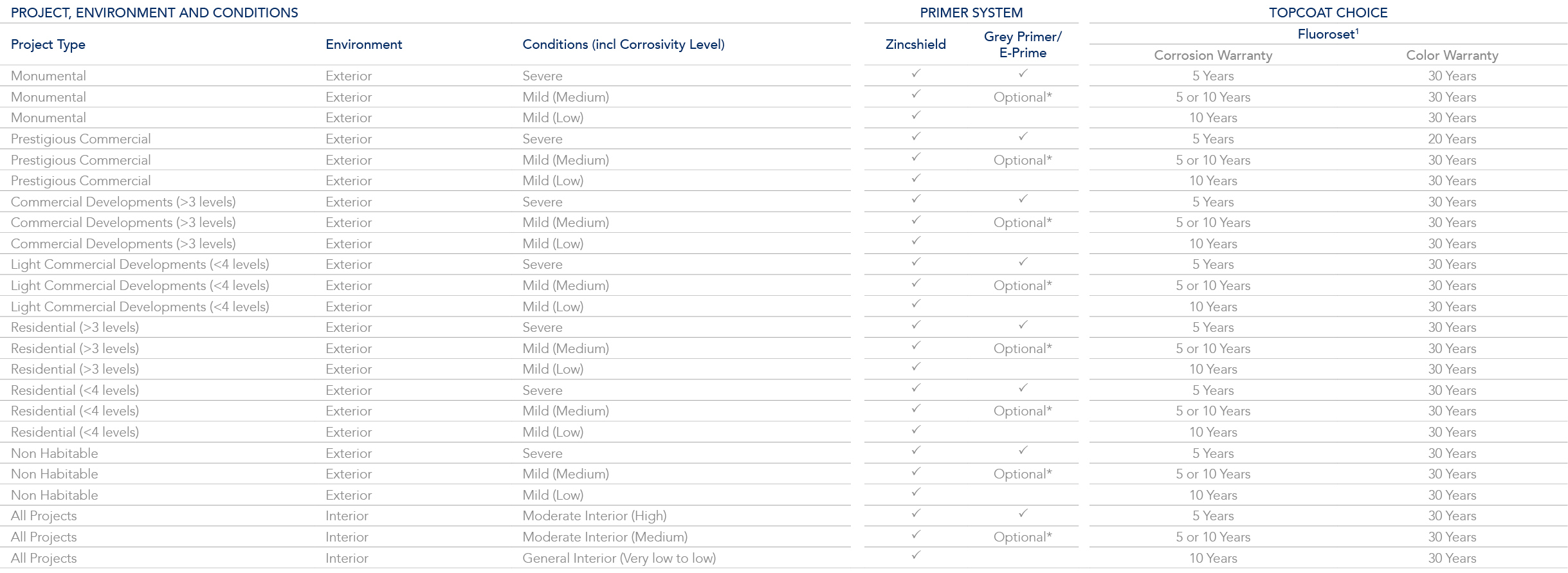

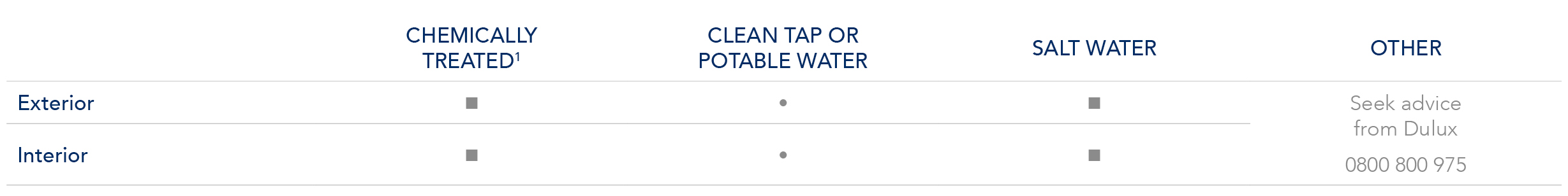

Use the tables below to determine the appropriate the product choice you have to gain a Alumi Shield™ warranty by determining the environment that your project will be exposed to. Use this together with the Dulux Macroclimate Corrosivity Corrosivity Zone Maps of New Zealand Guide, available here, the online Dulux SpecMap tool, available here.

Use the tables below to determine the appropriate the product choice you have to gain a Steel Shield™ warranty by determining the environment that your project will be exposed to. Use this together with the Dulux Macroclimate Corrosivity Corrosivity Zone Maps of New Zealand Guide, available here, the online Dulux SpecMap tool, available here. Click on the table below for a larger version.

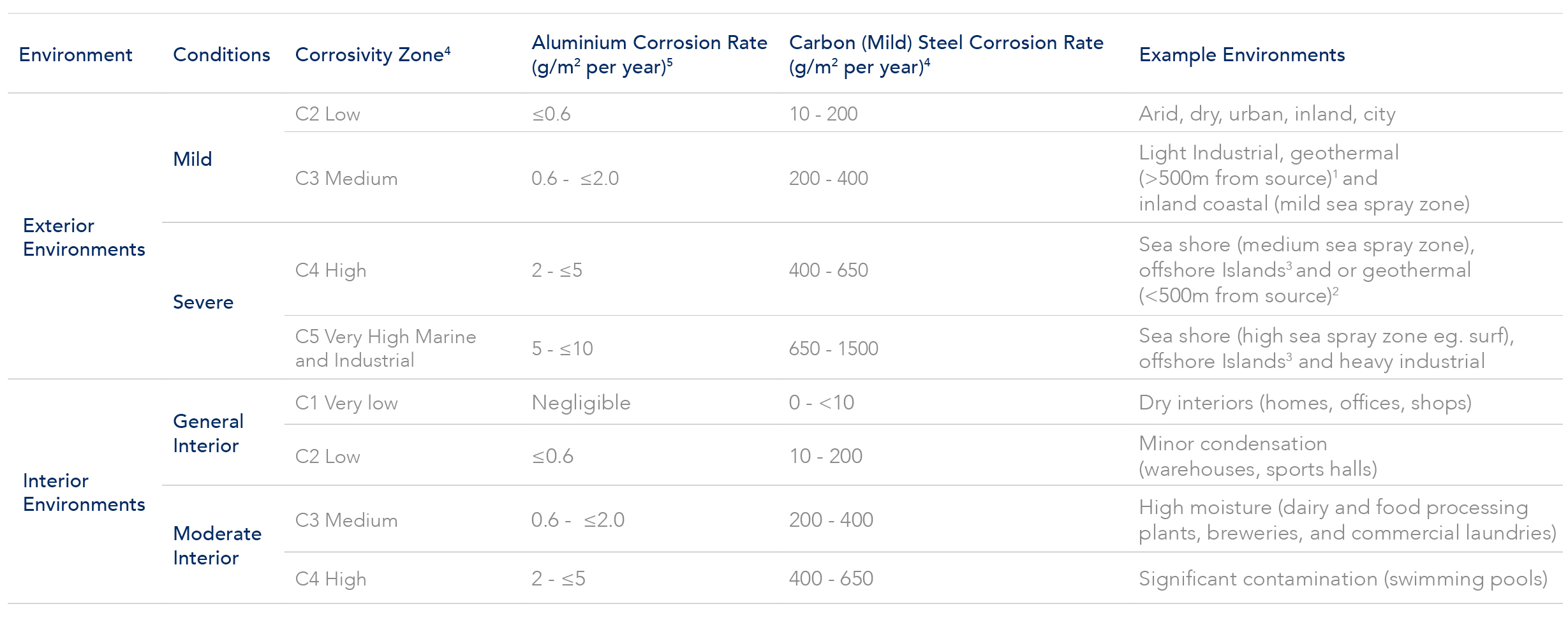

Use the following table which references AS 2312.1, SNZ TS 3404 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories. To pinpoint your projects corrosivity zone this table should be used together with the Dulux Macroclimate Corrosivity Zone Maps of New Zealand Guide, available here, or Dulux SpecMap tool available here.

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project.

Call 0800 800 975

Only Dulux Accredited and Dulux Prime Accredited Powder Coaters are able to issue our Dulux Alumi Shield™ and Steel Shield™ warranties after demonstrating their capability to meet stringent quality conditions and international standards.

For more information click here.