![]()

Note: Copol® is not part of the Dulux Alumi Shield or Steel Shield warranty programs. It is ideal for use:

Developed for use over various substrates including steel and aluminium on interior applications only.

Examples include interior furniture, shop fittings, industrial racking, tapware, and bathroom fittings. Copol solid colour products may also be used for inter-coat exterior applications not exposed to sunlight such as automotive under bodies.

Copol®

The pre-treatment process should be capable of meeting the performance outputs as described in AS3715. Compliance to appropriate process parameters is essential in ensuring compliance to etch, conversion coating weights (time/concentration) and conductivity of the final rinse.

The etch process is a very important stage of pre-treatment and close consultation with your pre-treatment supplier is strongly recommended to ensure optimum adhesion & corrosion resistance is obtained. As an approximate guide:

This is the next pre-treatment process for aluminium to ensure that it is suitably prepared for coating. It is recommended that Chrome conversion weights be a minimum of 431mg/m2, but advice from pre-treatment suppliers should be taken into consideration.

Final rinse is to ensure optimum surface preparation prior to coating.

Care should be taken with handling to ensure health and safety measures are met and that the substrate is not contaminated.

Dry Off Oven (if applicable) If your site uses a dry off oven to assist in the pre-treatment process please ensure:

| Metal Temperature (°C) | Time (minutes) |

| 210° | 8 mins minimum |

| 200° | 10 mins minimum |

| 190° | 15 mins minimum |

The following table can be used to help identify if Copol is suitable for your project.

![]()

The following table can be used to help identify if Copol is suitable for your project.

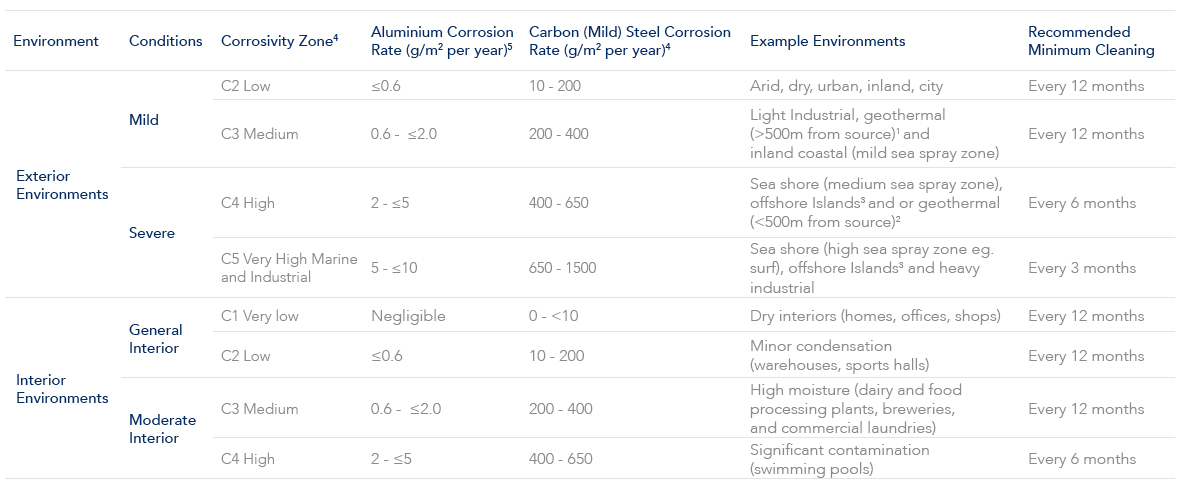

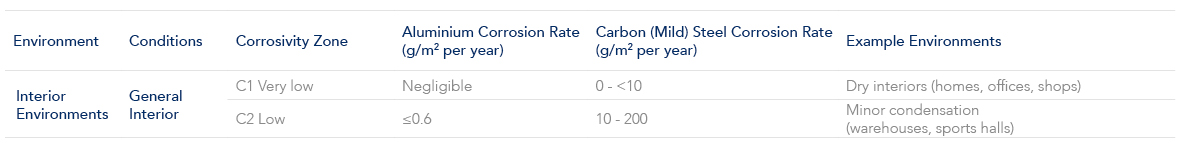

Use the following table which references AS2312.1, SNZ TS 3404 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories.

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project.

Call 0800 800 975

Tough, chemically resistant finish for interior applications only, delivered with modified epoxy thermosetting powder. Recommended usage includes shop fittings and industrial racking. Solid colours may also be used for inter-coat exterior applications not exposed to sunlight such as automotive under bodies.

Flat

95351677

Satin

95357243

Satin

95385178